RUST PROOFING AND CORROSION PROTECTION IN BUFFALO, NY

Details to Consider Before Galvanizing Services

Before you use galvanizing services, there are some details you should take into consideration. For example, you should consider if there have been coatings such as paint on your materials and if there are holes within your materials. Ideally, your items should not have any previous coatings of primer, oils, and paints. Likewise, your materials should have vent holes to ensure the solution can coat evenly.

For more information on all the details you should consider before galvanizing services, please review the content on this page. If you happen to have additional questions, please do not hesitate to contact our hot dip galvanizing professionals. We understand that preparing your materials for corrosion protection, rust proofing, and zinc coatings can be confusing at times. However, our team is more than happy to answer your questions and make sure your materials are properly prepared.

The hot dip galvanizing process may be complex, but we try to make it as simple as possible for our customers. Get in touch with our professionals based in Buffalo, NY! We also invite you to check out our portfolio page to get a better idea of our capabilities.

DESIGN CONSIDERATIONS

All material must arrive free of any paint, lacquer, primer or oil, as these will not come off in our hydrochloric cleaning baths. Should your material have any of these coatings, the material will need to be blasted prior to arrival. Rust, scale and dirt are safe and will come off in our cleaning baths.

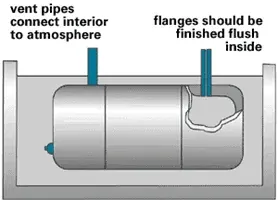

VENTING & DRAINAGE

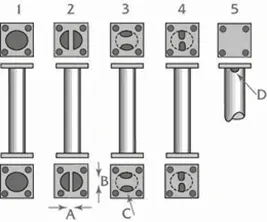

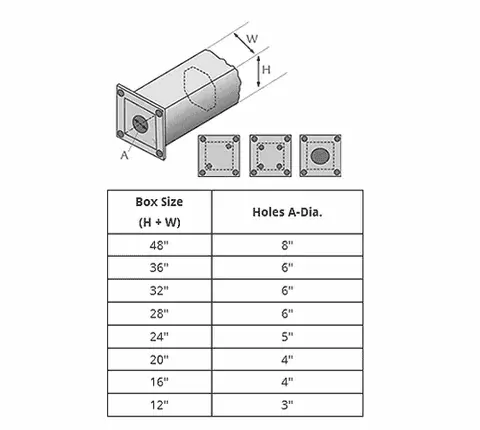

In the hot dip galvanizing process, steel is treated with a corrosion-inhibiting zinc coating. The zinc forms an abrasion-resistant metallurgical bond with the base steel. In order to ensure that all interior and exterior surfaces are protected from corrosion, the whole fabrication is lowered into cleaning solutions, flux solutions, and molten zinc metal. To facilitate interior and exterior cleaning and coating, there must be holes in the fabrications to be galvanized.

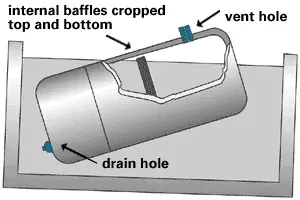

The foremost reason for vent and drain holes is to allow air to be removed from inside the fabrication, allowing it to be fully immersed in the cleaning solutions and molten zinc. This way, the excess zinc and solutions can drain out and away from the part.

Additionally, if fabrications are not properly vented, cleaning solutions or rinse waters trapped in overlapping or contacting surfaces may flash to steam. The resulting pressure increase (up to 3600 psi [25MPa]) can rupture the fabrication. All trapped moisture that flashes to steam will often result in localized uncoated surfaces.

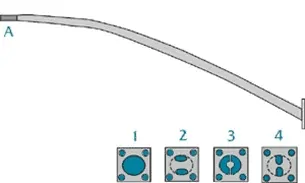

Since galvanized items are immersed in all cleaning solutions at an angle, vent holes should be present at the highest point of the fabrication. You should also provide drain holes at the lowest point (as mounted during the galvanizing process).

For more information on our hot dip galvanizing process or other services, from metal coating, corrosion protection, and powder coating alternatives to zinc coating, steel protection, and plating alternatives, contact our offices in Buffalo, NY today.

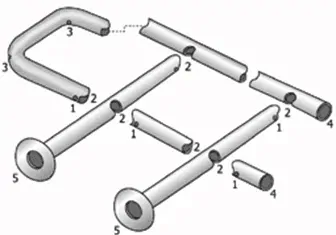

Vertical Sections

Vertical Sections